ME730 - Ultra Precision Machining

Instructor

S.S. Joshi

Semester

Spring ‘20

Course Difficulty

The course is easy to follow and structued well. Content is moderate, not very difficult but conceptual.

Time Commitment Required

Quizzes are scheduled outside class hours once every two weeks. 2-3 hours of reading slides/revision every week is more than enough.

Grading Policy and Statistics

Very chill. 60% with and above AB in ‘20 and 50% for the same in ‘18

Attendance Policy

No attendance policy in online mode.

Pre-requisites

Basic knowledge(which is covered in core courses) of manufacturing processes helps. Knowing some simulating software like Ansys or ABAQUS is a plus but not necessary, TAs are helpful and conduct tutorial sessions.

Evaluation Scheme

No midsem. Best 4 out of 6 quizzes (40%), Endsem (40%), Project(20%). A viva was skipped in ‘20, can be included next year.

Topics Covered in the Course

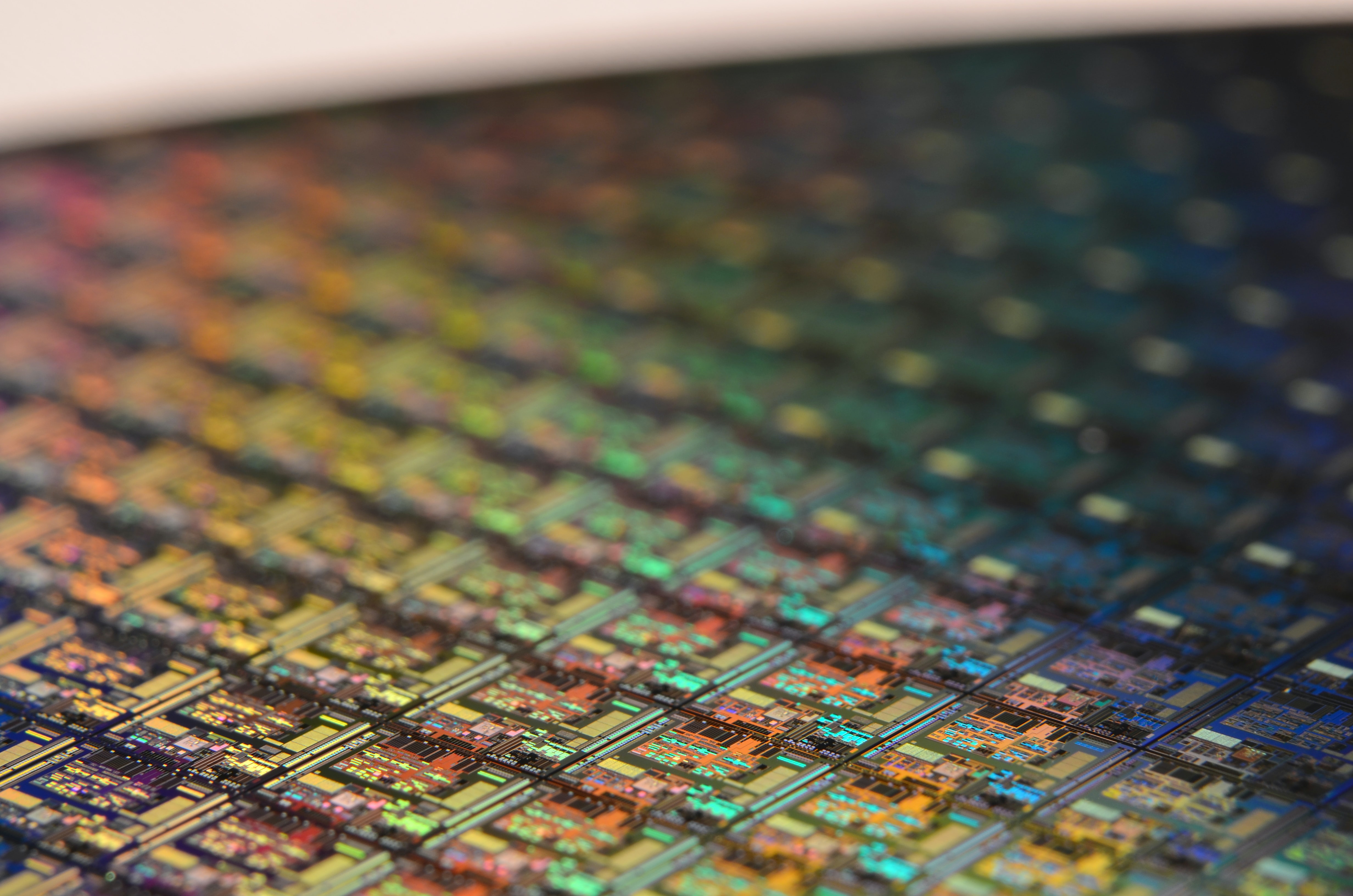

This course specifically focuses on atomic scale machining/processing. Nano and micro level mechanical and chemical processing are discussed. Some Nano measuring methods like STM are also covered. Some specific topics are: Atomic-bit and atomic cluster processing methods, Mechanism of nano-mechanical processing of atomic clusters, Nano-processing systems like diamond turning, grinding, ultra precision polishing, manufacturing of Si wafers etc.

Teaching Style

Slides are used and reference books are listed. Teaching is easy to follow and pace is good. The quizzes ensure regular revision which is necessary considering the content and it’s scope. TAs are very helpful

Tutorials/Assignments/Projects

Project is evaluated over the semester, hence there is no load and it isn’t rushed at the end. The topic is typically finalized by midsem and work updates are expected by TAs and professor. Expected projects are machining simulations on softwares like ABAQUS which can be validated using results from a research paper or an analytical model. Projects can also be analytical in nature, where a research paper’s mathematical model is simulated in python/MATLAB and results are validated/compared with experimental results. A thorough report is expected. Presentation and Report carry equal weightage.

Feedback on Exams

Quizzes are numerical and reasoning based. Easy to score if syllabus is thoroughly looked at once.

Endsem contains a mix of difficult and easy questions. A lot of content is covered up by the end and it might become difficult to remember everything, making notes can be very beneficial.

Motivation for taking this course

Learning about Nanotechnology, and atomic level machining and measuring. Highly evolving area of research. Good scope.

How strongly would I recommend this course?

It is different from other manufacturing courses and it covers important concepts that are specific to nano scale machining. Has lots of research opportunities. Professor Joshi is very approachable. So, I’d suggest anyone interested in nanotech or machining to take this course.

When to take this course?

8th semester. 6th or 8th semester is good.

References Used

N. Taniguchi, Nanotechnology: Integrated Processing Systems for Ultra-precision and Ultra-fine Products, Oxford University Press Inc., NY, 1996.

J. McGeough, Micromachining of Engineering Materials, Marcel Dekker, Inc., NY, 2002.

M. C. Shaw, Principles of Abrasive Processing, Oxford: Clarendon Press, 1996.

ME 730 Review By: Sankalp Aloné