ME206 - Manufacturing Processes 1

Instructor

Pradeep Dixit

Section

S1

Semester

Spring ‘19

Course Difficulty

Moderately easy

Time Commitment Required

Not much apart from lectures, reviewing the content a day or two before the exams would suffice

Grading Policy and Statistics

Grading was quite reasonable.

In a class of 60, about 10 people got an AA, a further 15-20 got AB and BB each.

Attendance Policy

Attendance wasn’t compulsory

Pre-requisites

None, although some ideas from ME221 were carried forward

Evaluation Scheme

Since the semester was truncated, the modified weightages weren’t disclosed. The main components, however were:

3 quizzes

3 assignments

Midsem

Project

Topics Covered in the Course

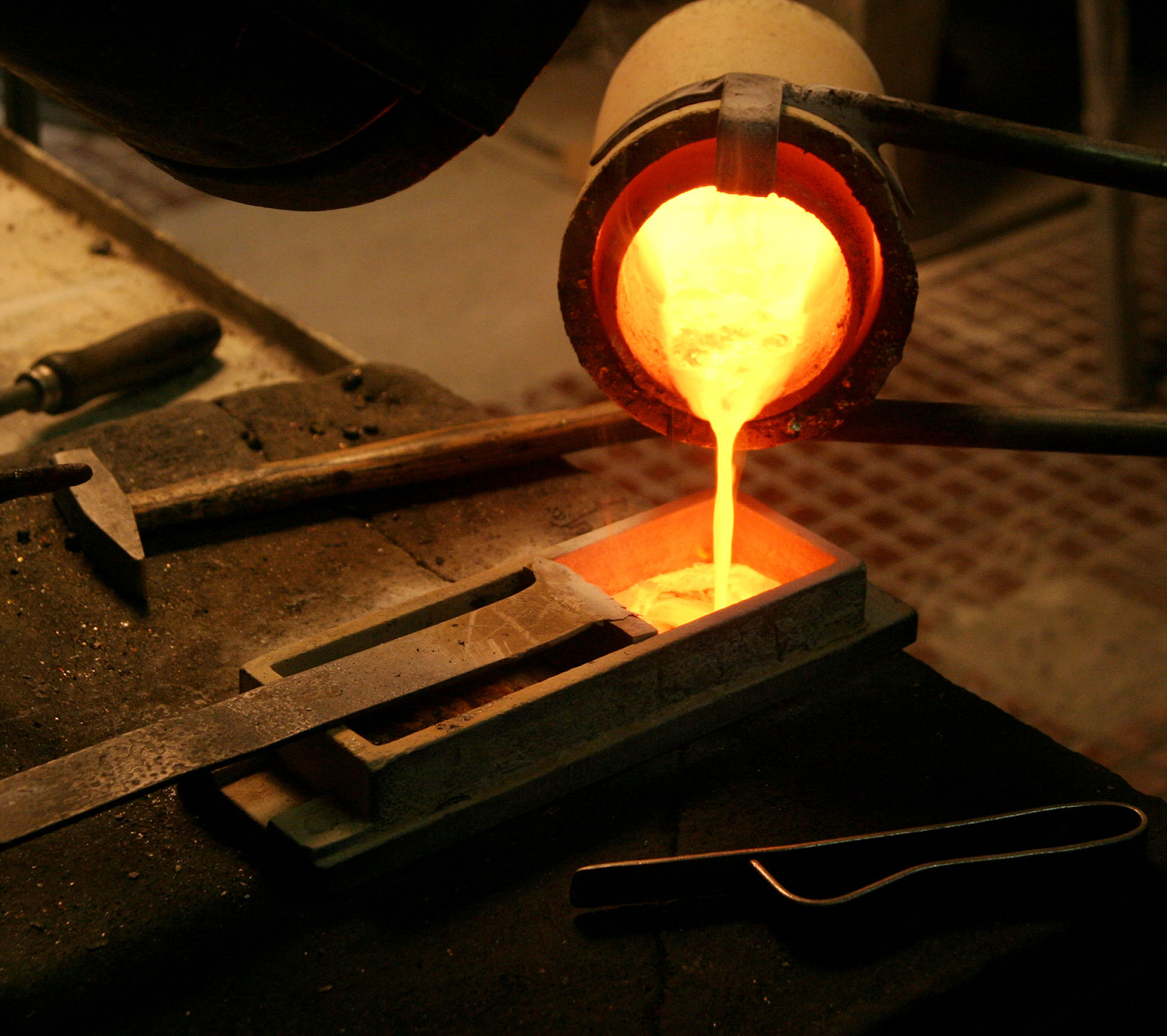

Casting processes: dispensable and permanent mould processes; analysis of melting, pouring and solidification phenomena; design of pattern, core, feeder and gating system; casting defects and inspection. Joining processes: fusion and solid-state welding; brazing and soldering; weld joint design, cooling rate, and joint properties; welding defects and inspection. Bulk and Sheet Forming processes: rolling, forging, extrusion and drawing; sheet metal working; forming limit diagram; loads, friction and lubrication; forming defects and inspection. Powder processing: Powder manufacture, characterization, compaction and sintering; metal injection moulding; hot and cold isostatic pressing. Polymers and Composites: Thermoplastics, thermosets, elastomers and composites; related processes; injection mould design; moulding defects and inspection. Advanced processes: Free form fabrication (rapid prototyping), and net shape manufacturing processes.

Teaching Style

Live lectures were conducted and slides were provided. The slides were typically very long with loads of content - about 80 slides per lecture and 10 lectures till a week after midsems. The professor would typically read the slides and paraphrase them briefly, so lectures were not very interesting.

Tutorials/Assignments/Projects

Assignments were typically questions from old GATE papers and would be highly numerical.

The project was simulation-based, wherein we had to (in groups of 3) simulate the casting of two objects of choice on the E-Foundry online platform. Certain calculations had to performed based on the simulation.

Feedback on Exams

Quizzes were a mixture of objective-type questions (with negative marking) and long subjective questions.

The midsem had 40% theory questions, wherein one was expected to have memorized the contents of the slides to a good extent. Some questions were outside the slides as well. The remaining part of the midsem was a series of long arduous calculation-heavy questions.

While grading subjective questions, a large proportion of the weightage was assigned to the final correct answer, so a small mistake could lead to getting 0 out of 6/8 mark questions.

Course Importance

ME206 is essential for the immediate follow-up ME338, another core course. The two of these then come in handy during ME374, the Manufacturing Processes Lab.

Going Forward

This course is the first serious course in the CIM area of the department curriculum, so if you like this course, you can explore more CIM electives.

References Used

Manufacturing Science by Amitabha Ghosh (several obscure formulae and definitions would come up in the exams, straight out of this book)

Manufacturing Engineering and Technology by Kalpakjian and Schmid

ME 206 Review By: Aditya Iyengar