ME206 - Manufacturing Processes I

Instructor

Shyamprasad Karagadde, Sushil Mishra and A. Alankar

Section

S1; sections were allotted based on students’ choice (both sections were taught by the same set of instructors and the grading was common to both sections)

Semester

Spring

Course Difficulty

Moderately difficult. The course is an introduction to some of the manufacturing processes, and not very rigorous.

Time Commitment Required

4-5 hours per week including lectures

Grading

Lenient

Attendance Policy

No DX grade was given. 4% bonus marks were given for attendance >90%, 2% bonus for 80% < attendance < 90%

Pre-requisites

None

Evaluation Scheme and Weightages

- Quizzes + Assignments - 39%

- Midsem - 21%

- Endsem - 40%

Topics Covered in the Course

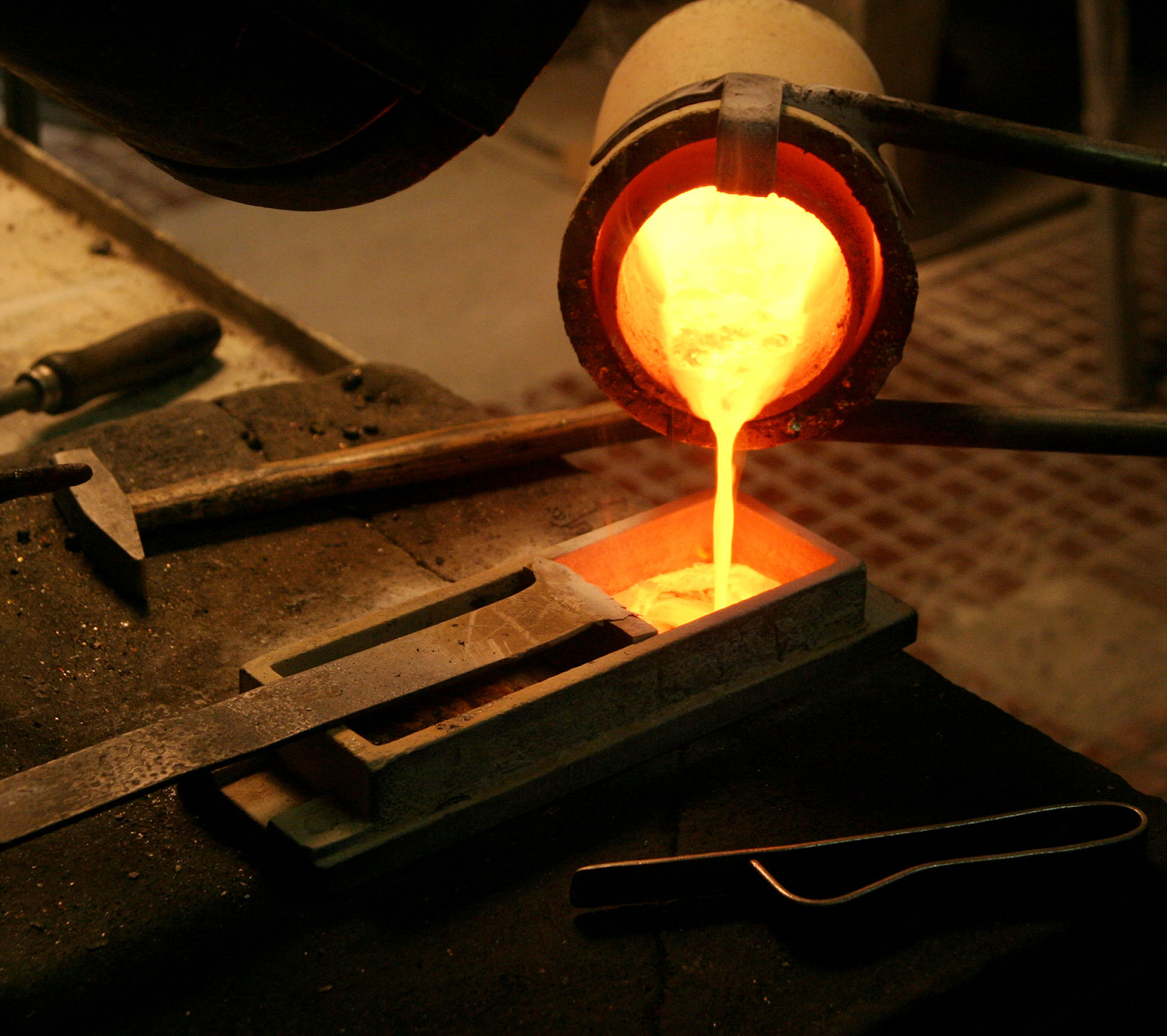

Casting, Freeform fabrication, Joining, Powder processing, Forming, Polymers and Composites

Quality of Lectures

The semester was divided into 3 (fairly equal) parts:

- Casting and Free Form Fabrication - Prof. Karagadde (used both slides and the board for teaching)

- Joining and Powder Processing - Prof. Sushil (largely used slides)

- Forming and Polymers and Composites - Prof. Alankar (largely used the board for teaching, but also uploaded his extensive notes for reference)

Assignments and projects in the Course

Easy

Exams

Easy. The exams were very relevant to the content taught in the class and involved some innovative thinking (which manufacturing process can be used for what purpose, pros and cons of various process, and some mathematical problems)

Reference Material

- Mikell P. Groover, Fundamentals of Modern Manufacturing: Materials, Processes, and Systems, 2006

- Ghosh A. and Mallick A. K., Manufacturing Science, Affiliated East West Press, 2001.

- Class notes (highly recommended)

Importance of Course

A great introduction to the field of manufacturing, many research opportunities available

Other Interesting Links