ME460 - Solid State Joining

Instructor

Prof. Amber Shrivastava

Semester

Spring ‘20

Course Difficulty

The course is pretty chill. Concepts are covered from the very basics, and thus, they should be easy to follow. Even if some lectures are missed, one can attend the subsequent lectures and won’t have much of a hassle understanding the topic.

The projects being individual might be a bit difficult at first glance, but little effort throughout the semester certainly helps. Besides, a much out-of-the-box/ novel solution is not expected by the Professor in the first place and one has to just try and replicate the papers provided.

The quizzes were easy, the questions asked were mostly in line with the preceding assignments. There was no midsem and the endsem had 4 questions, each from one of the 4 conducted quizzes.

Time Commitment Required

Minimal, just attending the lectures should be enough. Although some time input would be required for assignments and the project (~1 hour per week).

Grading Policy and Statistics

Pretty chill, 10/15 students got grades >= BB

AA 3

AB 4

BB 3

BC 3

FR 1

W 1

Attendance Policy

Attendance was not compulsory during the online semester, all the lecture slides and assignments were posted on Moodle.

Pre-requisites

None, although a basic coding knowledge (in any language) helps.

Evaluation Scheme

Assignment 15% (2 assignments)

Quiz 25% (Best 3 accounted out of the 4 conducted)

Project 20%

End semester examination 40%

Topics Covered in the Course

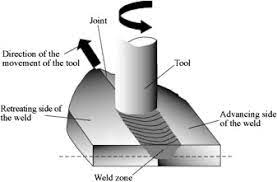

Fundamentals (thermo-mechanical processing, diffusion and adhesion mechanisms) of various solid state joining methods. Development of analytical and numerical models for certain selected processes. Understanding the applications, advantages and limitations of solid state joining methods.

Teaching Style

Slides and snippets of books/papers were used by the Professor to explain the topics during the lecture. Overall, the teaching was good, and the one-hour lecture time surely helped in keeping things interesting.

Tutorials/Assignments/Projects

There were 2 assignments in total. Transient and steady-state boundary problems had to be coded (MATLAB/ Python). A major chunk of the solution was already provided in the lecture slides, so the difficulty level of the assignments could be termed relatively easy.

The project is an individual one for which a list of topics (and the research papers) are floated by the Professor in advance. One has to choose the topic of their liking (First Come First Serve) and replicate the results in the given research paper.

Feedback on Exams

There was no Midsem. Best 3 out of 4 Quizzes were accounted for in the final grading. Endsem had one question from each of the 4 Quizzes conducted. Thus the exams are fairly easy.

Course Importance

The learnings from the course would be useful for the student for their future research work, particularly for manufacturing and simulation-based research.

How strongly would I recommend this course?

If one wants to learn a variety of joining processes from the very basics in a very concise manner without too much of a course burden, this is the course to take.

When to take this course?

I took the course in my 8th semester. The recommended semesters would be 6th and 8th.

References Used

Although not at all required for the students to read up on these, the resources suggested by the Professor were:

Jacob Lubliner, “Plasticity Theory”, Published by Pearson Education, 2008.

Helmut Mehrer, “Diffusion in Solids”, Published by Springer, 2007.

Lucas Filipe, Andreas Ochsner, “Modeling of Adhesively Bonded Joints” Published by

Springer, 2008.

Serope Kalpakjian, Steven R. Schmid, “Manufacturing Engineering Technology”

Published by Prentice Hall, 2001.

Review By: Rohan Singh